The scientifically proven technology in PREXELENT® brings antimicrobial properties to fully customized polymer solutions

Pinetree rosin* is well known for its antimicrobial properties. It is our hero ingredient and the starting point for our innovation.

PREXELENT® technology with rosin in plastics is efficient against many kinds of harmful microbes – mold, viruses, and bacteria.

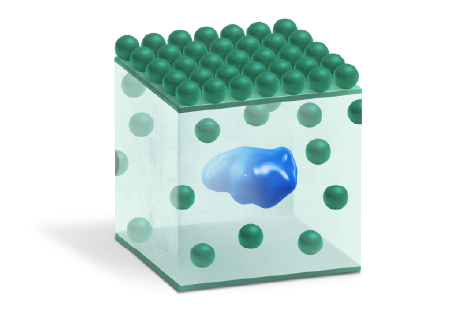

The technology in PREXELENT® is unique. We don’t just mix rosin with plastic, and it is not a coating solution, but have found a way to store the rosin inside the plastic and migrate it to the surface in a controlled manner. We can develop unique solutions for your business with different forms and polymers, combining our 40 years of experience in polymer modifications and a dedicated team of professionals with PREXELENT® technology.

Applicable

Polyolefins

(LDPE, LLDPE, MDPE, HDPE, EVA, EBA, EEA, PP)

Polystyrens

(PS, ABS)

Engineering plastics

(PA 6, PA 12)

Thermoplastic elastomers like TPU and SEBS.

PVC is applicable,

but not at Premix’s factory

Not applicable

PET, PEEK, or PA66 due to their high melting point

The material's composition is modified so that rosin, the active agent, migrates to the material's surface at a chemically controlled rate, where it is activated by humidity or liquid. The release rate of the active agent can be modified to meet the needs of different applications. PREXELENT® is compatible with machinery and processes in common use and is manufactured in a so-called melt compounding process, in which an active antimicrobial agent is processed straight into the plastic. The resulting material can be further processed in the same way as plastics in general, including injection molding or extrusion, into different shapes and forms.

* Rosin is not registered by the EU as a biocide

SAFE

Rosin can be used

in both feed and

food contact in

the EU.

A patented method of mixing

an antimicrobial active agent

with polymers.

PREXELENT® technology offers

numerous application

opportunities.

A sustainable choice to

bring antimicrobial properties

to the surface of polymers.

The latest innovation from

Premix Group with 40 years of

experience in polymer modification.